Iron Ore Leases

Iyli Gurunath Iron Ore Mines of RMML

RMML Iyli Gurunath is an opencast Iron Ore mine spread across 20.23 hrectares in Sandur taluk. The mine produces 0.50 MT iron ore annually.

Karadikolla Iron Ore Mine (KIOM)

Karadikolla Iron Ore Mine (KIOM) extends to an area of 86.059 hectare was won in e-auction process during 2016 after the amendment of MMDR Act in 2015 for captive consumption as per the directions of Honble Supreme Court Mining lease has been executed during February 2020. The validity of mining lease is for 50 years.

The Run of Mine (ROM) of this mine is subject to screening and secondary crushing and shall be dispatched to the MSPL pellet plant for pelletization. The chemical composition of processed ore with Wt. Avg grade is around 54.5 per cent Ferrum.

Jaisingpur Iron Ore Mine (JIOM)

Our Jaisingpur Iron Ore Mine (JIOM) is spread across 56 hectares. This mining lease was granted by the Government of Karnataka for 50 years for non-captive use through e-auction process. The mine is 3 km from Jaisingpur village, 16 km from Hospet district head quarter and 22 km from nearest rail head s Kariganur. The production capacity of the mine is 0.12 MTPA . The entire run of mine (ROM) is subjected to crushing and screening. Processed ROM will be sold in the open market.

Ramdev Iron Ore Mine (RIOM)

The expanse of Ramdev Iron Ore Mine (RIOM) is 30.09 hectares. This mining lease has been won in e-auction conducted by the Government of Karnataka for 50 years for captive use. MSPL Limited has obtained all statutory approvals except forest clearance which is in process. Mining Lease shall be operative after the forest clearance.

Narasimha Iron Ore Mine (NIOM)

Narasimha Iron Ore Mine (NIOM) extends to 60.66 hectares. This mining block has been awarded through e-auction system for 50 years for captive use. MSPL Limited has obtained all statutory approvals except forest clearance which is in process. Mining Lease shall be operative after the forest clearance.

Geology & Reserves: The production capacity of the mine is 0.77 MTPA. The mine has environmental clearance for 5 MTPA. MSPL Limited is setting up a downhill conveyor system, beneficiation plant and pellet plant at Somalapur village, Sandur taluk, Ballaridistrict.

Swamimalai Iron Ore Mine (SIOM)

Swamimalai Iron Ore Mine (SIOM) spans an expanse of 26.71 hectares The Government of Karnataka granted a mining lease for 50 years for captive use through e-auction. The mine is approachable by Sandur-Subbrayanahalli road, and the nearest village is Swamimali of Sandur taluk.

MSPL Limited has obtained all statutory approvals except forest clearance which is in process. Mining Lease shall be operative after the forest clearance. The production capacity of the mine is 0.319 MTPA. The run of mine produced from this mine will be crushed, screened, and dispatched to MSPL pellet plant for captive use. The chemical composition of processed ore with Wt.Avg grade 54.5per cent Ferrum.

Product Specifications

Since time immemorial, iron is a metal of widespread use. History shows that it has been the very pillar human civilization is built on. Different types of iron ore contain varying percentage of pure iron are present in nature. Generally, there are four types of iron ore categorized based on their iron content.

Following four varieties of iron ore are generally recognised.

1. Magnetite

This type of iron ore could contain up to 72 per cent pure iron. It possesses magnetic properties and hence is called Magnetite. It is found in Andhra Pradesh, Jharkhand, Goa, Kerala, Tamil Nadu and Karnataka.

2. Hematite

Hematite contains 60 per cent to 70 per cent pure iron and is found in Andhra Pradesh, Jharkhand, Orissa, Chhattisgarh, Goa, Karnataka, Maharashtra, and Rajasthan. This is widely used in sponge iron and steel making.

3. Limonite

Limonite contains 40 per cent to 60 per cent pure iron. It is of yellow or light brown colour.

4. Siderite

Siderite contains many impurities and has just 40 per cent to 50 per cent pure iron. However, due to presence of lime, it is self-fluxing.

Scientific Mining Practices

MSPL Limited is committed for use and advancement of scientific mining practices. We strive at designing our mines for sustainable, safe, and environmentally friendly practices in all our operations. We carefully to ensure that air, soil, noise, and water pollution levels are kept at a bare minimum.

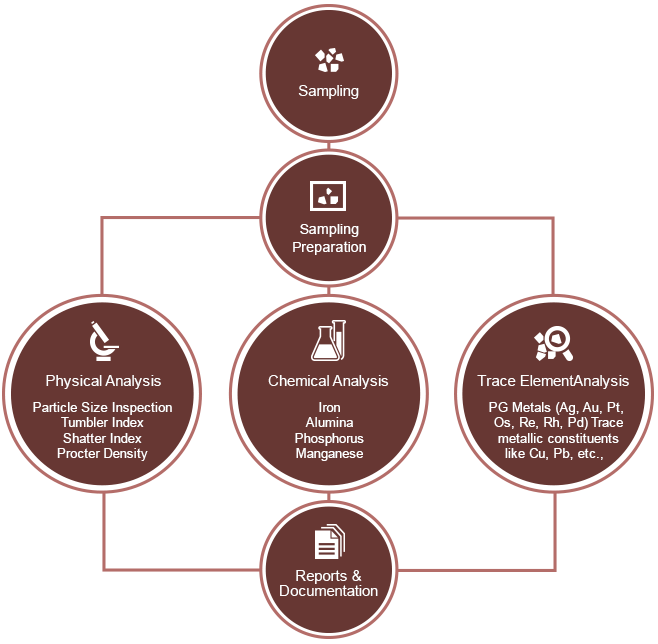

Quality Assurance

Quality is the principal objective of MSPL Limited. Our mines bears a stamp of quality and this is something we at Baldota Group consciously ensure. The guiding tenet is that, though the properties of the mine cannot be altered, but inferior grade ore can be enriched with spearheading technology to satisfy the demand of our clients.

Quality monitoring begins before mining. Precise geological exploration will be undertaken before the commencement of mining operations and the face samples shall be drawn and analyzed before we progress for blasting. Re check sampling and quality analysis also follows at the time of excavation, to confirm the exploration results.

The process plant is the next stage of sampling, where the proper working of the plant is assessed. The final product is then analyzed, before delivery, and the proper blend is ascertained. We are the first mining company to get an ISO 9001:2000 version endorsement. The certification stresses on customer satisfaction.

Research & Development

Overview

Our Research and Development (R&D) activity encompasses both iron ore and wind energy businesses. The general engineering expertise, ore dressing engineering excellence and deep knowhow in geology and metallurgy is the hallmark of our dedicated R&D team, which is our biggest asset.

Our state-of-the-art R&D lab features various instrumentation including testing equipment for iron ore and other elements. We conduct research on the use of iron and other minerals for purposes other than steel. Our laboratory has grinding and crushing equipment for the preparation of samples for testing.

R&D in our iron ore business includes attempts to enhance efficiency and reduce environmental impact of our mining. Through research, we also strive to find alternative uses for non-iron ore minerals extracted with iron ore, as part of our Zero-Waste Management initiative.

Our R&D laboratory is recognised by the Department of Environmental Sciences, Indian School of Mines, Dhanbad.

Way Forward

Consistently, our focus has been on reducing waste by converting low grade iron ore to high-value products. We strive to increase productivity and have zero tolerance for unsafe activities. We decrease the fuel and power consumption whilst minimizing the hazardous impact on the environment.

We ceaselessly work at zero-waste management in all mining and processing operations. We have established systems to maximise the recovery of the minerals available, through systematic mining, processing, and stocking. The R&D team has been very successful in achieving this goal.

We have to credit the development of diverse products like Hematite powder for use in the oil well drilling industry, and Sulpha Sponge, the most effective H2S scavenging agent for oil exploration, leather industries and refineries.

Sulpha Sponge has been patented with Register of European Patent. We are also rapidly expanding our product portfolio and are likely to shortly introduce pigments for use by the paint industry and Ferrite for use in the electronics industry.

Research on Banded Hematite Quartzite (BHQ)

Banded Hematite Quartzite (BHQ) is a low-grade iron ore with 35-37 per cent iron. Research is on to identify and establish beneficiation techniques. Further tests are in progress on semi commercial plants. Results of tests carried out by international laboratories, has confirmed that BHQ is amenable to beneficiation. At MSPL Limited, we have taken a decision to establish a BHQ beneficiation plant soon.