Narayana Health City , Bangalore

We have carried out trials of our product - Poly Sulpha Sponge - on 600 KLD Sewage Treatment Plant at Narayana Hrudayalaya Hospital, Bommasandra, Bangalore for the removal of foul odour and improvement of the treated water quality.

- The Poly Sulpha Sponge was dosed at the quantity of 20 mg/litre in the Primary & Secondary Aeration Tanks of the Sewage Treatment Plant

- The aeration was provided to the aeration tank through a diffused aeration mechanism for 8 hours.

- After 8 hours of extended aeration, the permeate was transferred to the clarifier tank and the Filter Feed Tank. Then the water is passed through the Pressure Sand & Activated Carbon Filters

- After this procedure, the permeate is measured for BOD and COD to ensure that it meets the pollution control board norms and that the water is checked with the Odour Meter. And it is observed as totally odor free.

TEXTILE WASHING PLANT AT DODDABALLAPUR APPAREL PARK

We have carried out trials of our product – Poly Sulpha Sponge – on textile washed effluent water, at the textile washing unit at Doddaballapur Apparel Park.

- The effluent was collected at the discharge point and loaded in the extended aeration tank which was filled with Poly Sulpha Sponge at 20mg/liter dosage.

- The aeration was provided to the aeration tank through a diffused aeration mechanism for 8 hours.

- After 8 hours of extended aeration, the permeate was transferred to the settling tank to allow any suspended solids to settle down at the bottom. The water is then passed through the pressure sand bed filter

- After this procedure, the permeate is measured for BOD and COD to ensure that it meets the pollution control board norms and that the water is totally odor free.

- The same trials were conducted by CLRI and the results matched with the trials conducted on site.

Report Analysis

DOMESTIC SEWAGE WATER TREATMENT AT SOG COLONY, DAVANGERE

The operations were conducted under the able guidance of the Executives of the Davangere Municipal Corporation for 7 days and the results were indeed encouraging and consistent.

- The sewage in the SOG colony, in Davangere, is CONNECTED to the main drain through the open drainage system. The sewage water is collected from the main drain chamber and transferred to the extended aeration tank, loaded with Poly Sulpha Sponge.

- The sewage water is then aerated with a diffused aeration mechanism for a duration of 8 hours and the permeate is taken to the suspended solids settling tank.

- The water is further passed through the pressure sand bed filter and tested to meet the stipulated norms of the pollution control board.

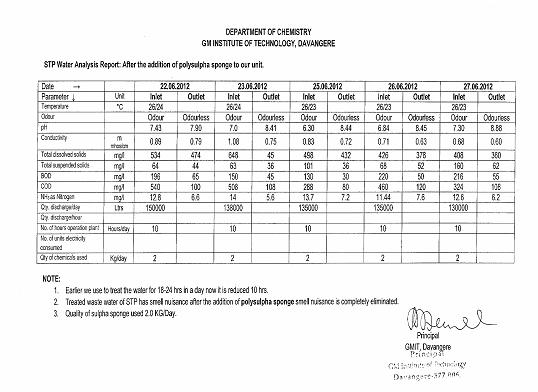

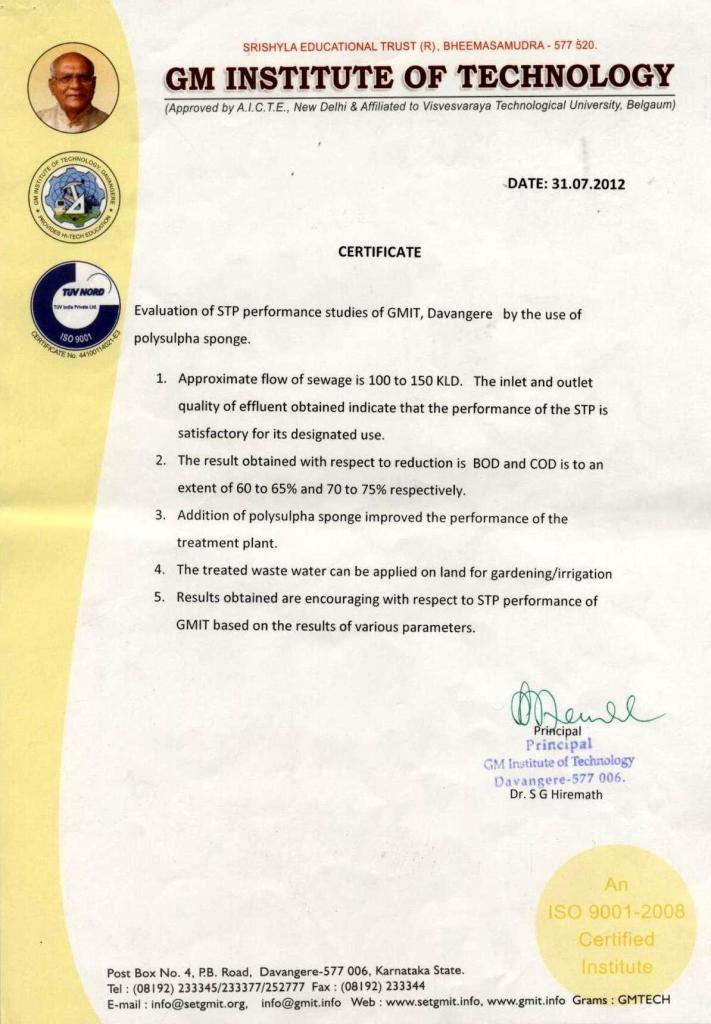

SEWAGE WATER AT GM INSTITUTE OF TECHNOLOGY IN DAVANGERE

As per the KSPCB directions in presence of the Environmental Department of GMIT We have taken the trials 100 KLD STP Plant.

Poly Sulpha Sponge added Dosage @20 mg/l in the aeration tank and provided 8 hours Aeration & then allowed for 2 hours settling in the Secondary Settling Tank. The Overflow Water from Secondary Settling tank is collected into the Filter feed tank, where chlorine is added for disinfection. The Water from Filter Feed tank is pumped into the Pressure sand Filter (PSF) for the removal residual Suspended Solids. The treated water from PSF is taken into the Activated Carbon Filter (ACF) for the removal of excess Chlorine& Odour. The final treated water from Activated Carbon Filter is free from odour & reduction of COD, BOD levels about 75-85 % .

Report Analysis

Certifications

MADURA GARMENTS

Aditya Birla group of Garments Industries at Bangalore two units one from Madura Garments,Anekal and English unit,Bannerghatta Road Bangalore

We have supplied the chemical for the ETP treatment for the both the units: We have treated Raw water with PSS in the 50 KLD plant,By adding PSS @ 20 mg/litre after treatment, out let water is free from Odour, the substantially reduction in the COD, BOD and Hydrogen sulphide.

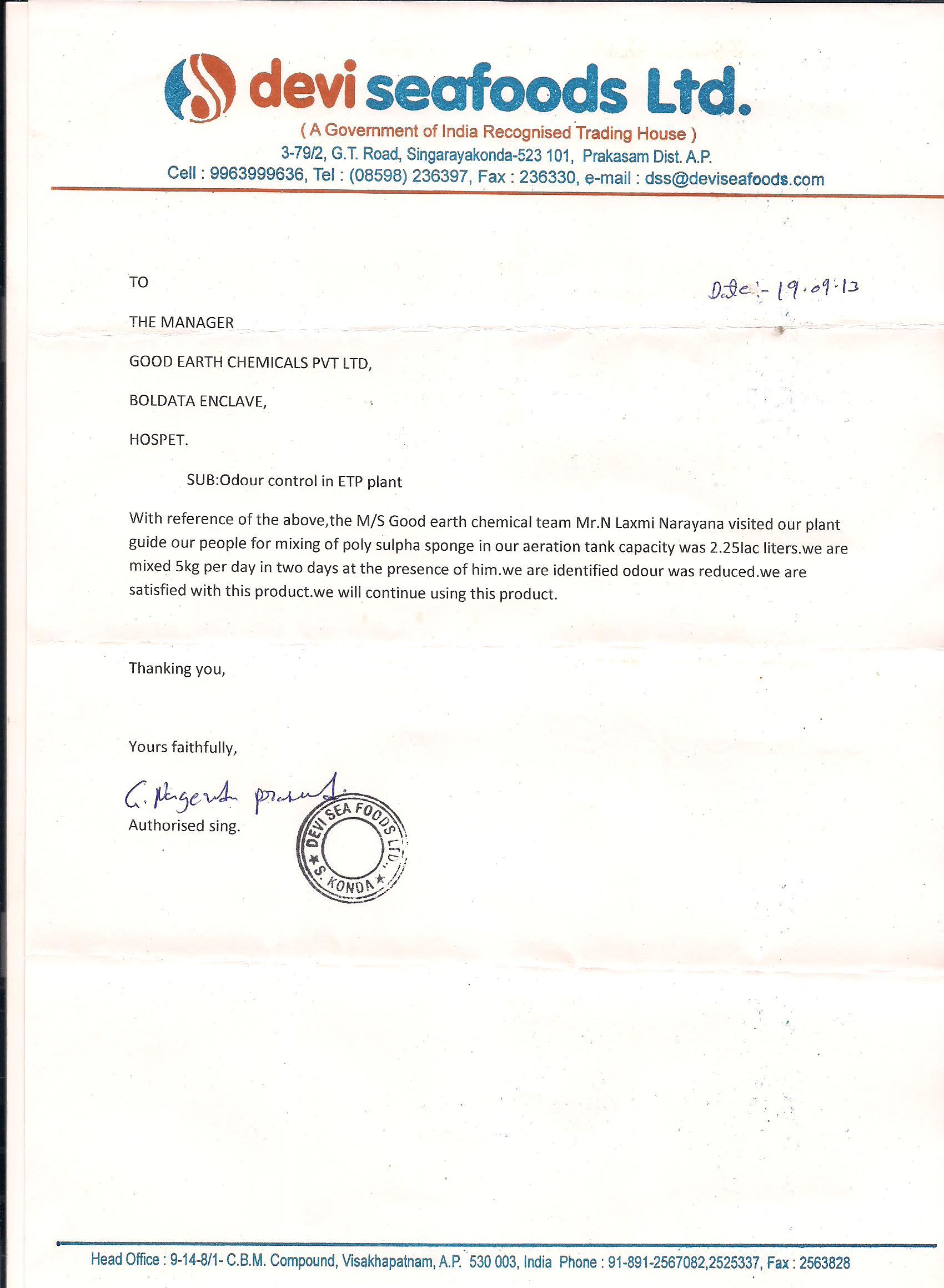

DEVI SEA FOODS

Devi sea foods is located at Singarayana Konda, A.P. The Prawn Export Company has issues of Odour in the entire plant, and with their approach, we supplied PSS to treat the ETP water.

After PSS treatment for five days for 200 KLD plant, they found reduction in the Hydrogen Sulphide and sludge was settled in the aeration tank itself. They were happy about the reduction of Odour in the surrounding of the unit.

PSS dosage in the Aeration Tank

Prawn washing Unit

Certifications

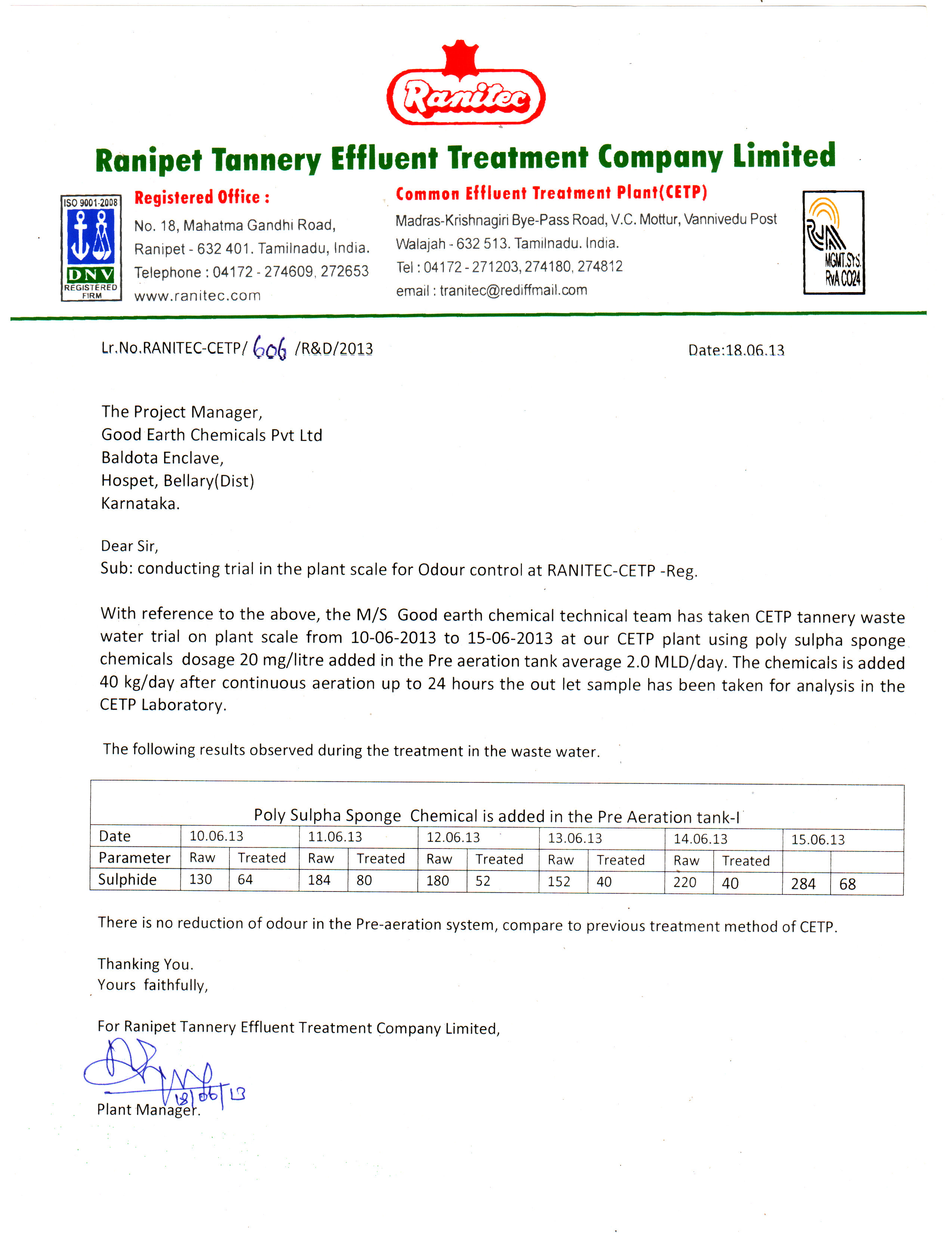

RANITEC TANNERY UNITS, TAMIL NADU

Ranitec is a CETP plant having capacity of 5 MLD with two aeration tank of capacity 2.5 MLD each.We have treated the plant with PSS in the primery aertion tank daily @20mg/litre. After treatment for 10 days, we checked the required parameters.

The plant Officials were satisfied regarding the Odour reduction surrounding the plant and tested the five days air monitoring to test the contamination of Hydrogen sulphide and results are very much encouraging,testing report is enclosed below.

Certifications

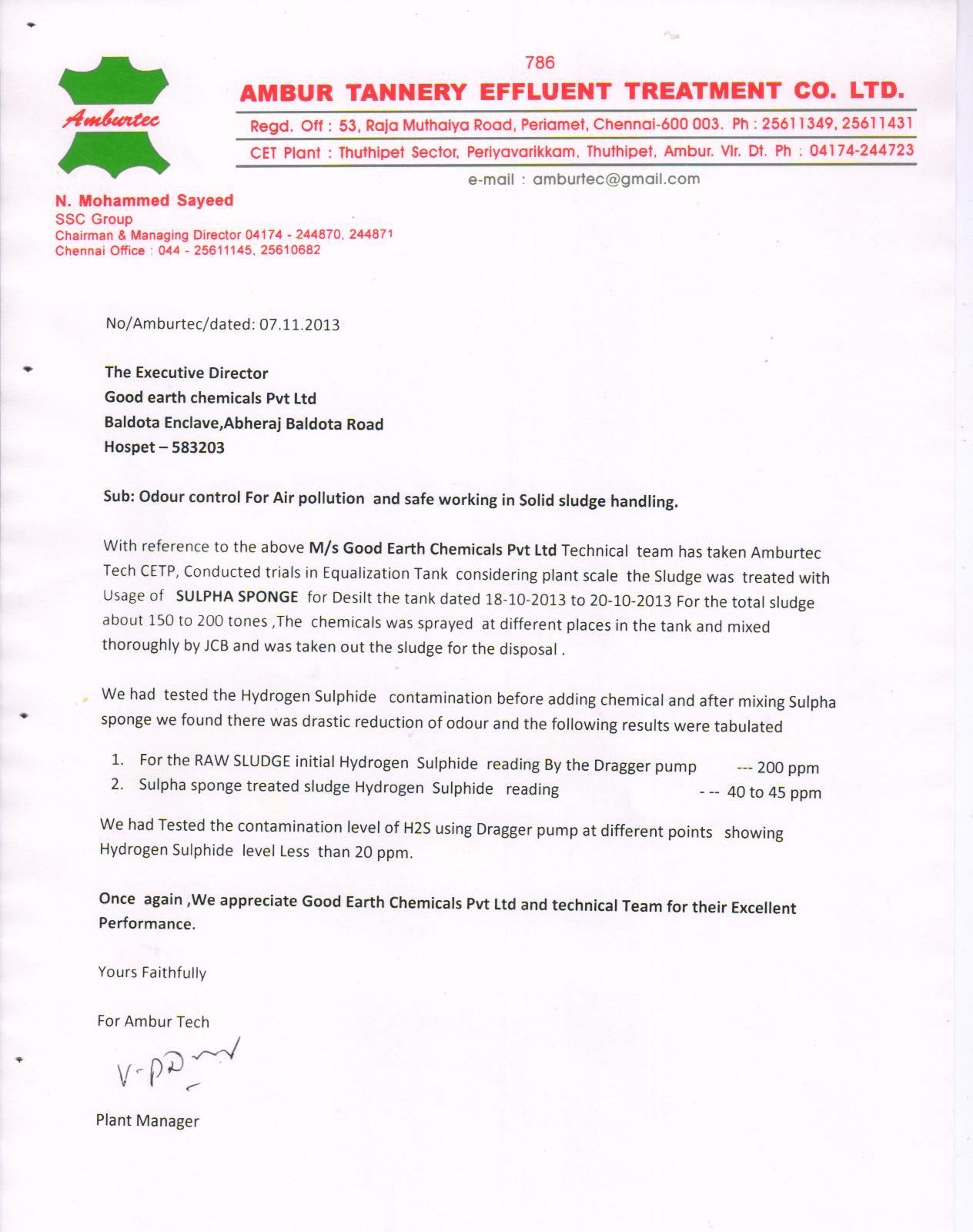

AMBURTEC TANNERY UNIT, TAMIL NADU:

Amburtech 2 MLD ETP plant set down was taken for the removal of sludge which is accumulated in the Equalisation and aeration tank about 50% to the capacity of the volume. The plant manager approached us on how to handle the sludge which contains heavy Hydrogen sulphide. We treated the entire plant with 1000 kg of Sulpha Sponge for two days , and there was a drastic reduction of hydrogen sulphide tested by Draggers gun. Before treatment, it was more than 250 ppm and after our treatment it came to 20 to 30 ppm. With this condition, workers started the de- silting work.

Certifications

Video

HIMATSINCA LENIN, HASSAN

Himathsinga textile factory at Hasan had a Odour issue from ETP sludge.

They approached us through the KSPCB reference. They had total 50 to 60 tonnes of sludge is accumulated. After our product Sulpha sponge treated the sludge Odour is reduced up to the satisfaction level of the staff and worker in the factory.

KITTUR RANI CHENNAMMA POULTRY, BELGAUM

The Managing director of the Kittur rani chennamma Poultry form at Kittur has taken our product reference from the KSPCB, approached us to treat the litter for the reduction of Odour around the poultry the form.

We gave demo for the treating of litter with sulpha sponge, after 2 hours Initial and after treatment the factory staff and worker are satisfied about the reduction of odour from treated litter.

SHAHI EXPORTS, BANGALORE

The Shahi exports are the leading garment exporters; they had odour issue in the ETP plant to treat on the sludge. After our Product Sulpha Sponge treated to the sludge, they are satisfied Odour reduction.

AKSHAYA PATRA, HUBLI

Akshayapatra is a project of ISKON which provides mid day meal to school Children’s around the Places. Here we supplied 100 KLD ETP Plant based on PSS Technology to treat the Wastewater. This Project is successfully commissioned.

The is running with full capacity to the requirement.

AKSHAYAPATRA, LUCKNOW

Akshayapatra is a project of ISKON which provides mid day meal to school children’s around the places. Here we supplied 75 KLD ETP Plant based on the PSS Technology.This project is under execution.

TATA

TATA Power STP Capacity 30 KLD errected & commissioned successfully.

Report of Analysis

BONE INDUSTRY

Malegaon, Maharastra: At Malegaon town main business is Bone processing factories are more per month 800 to 1000 tonnes they store in the big goodowns. The MSPCB had issued a closer notice the factories because of air pollution due to Objectionable Odour. They have taken our product on MSPCB reference.

We have given demo how to use our product Sulpha Sponge.

We have Taken 100 kg two lots of fresh unloaded Bone from the lorry; Sulpha Sponge was mixed thoroughly to the Bones. After 2 hours the Treated Bone lot checked for the Odour by the owners of the factories and workers, they were satisfied in the reduction of the Odour.

WATER TREATMENT PLANTS

Supplied the RO water Treatment plant to following villages under the CSR activity to serve the Public to provide drinking water facilities,Kavihalli,Hosahalli,Kalahalli,Hosaningapur,allvarthi,Danapur,Hanumanhalli Chittawadigi and APMC Hospet

This water passed through the ro, it meets the potable water specification